Customised special production of profile track rollers keeps the curing robot in cheese production moving.

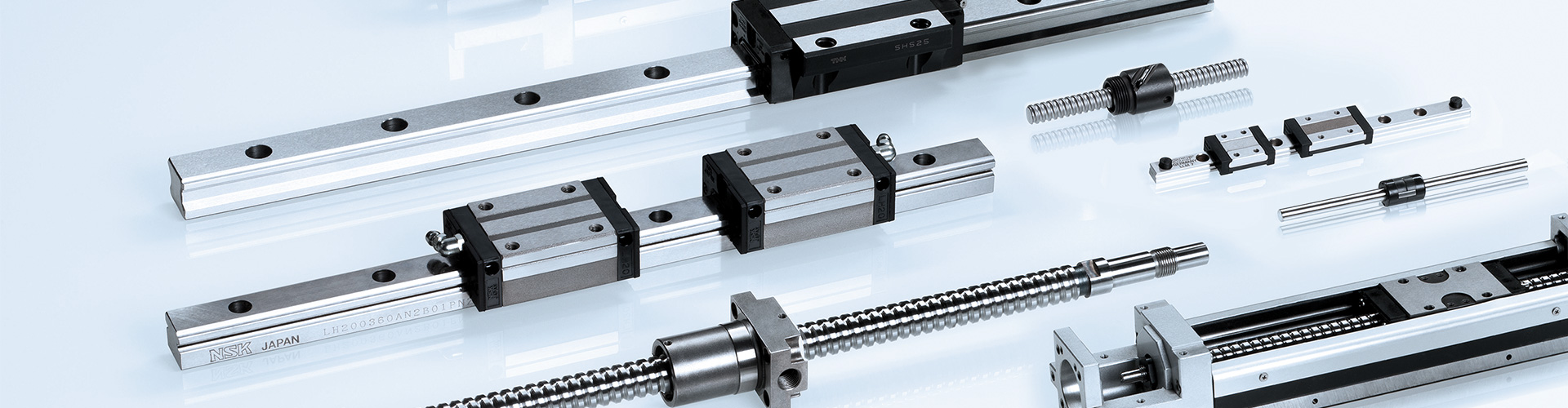

A food industry customer tasked us with finding an inexpensive alternative for the wear parts for their “cheese curing robot”, which are regularly required. Linear guides used in food production have to meet stringent demands: corrosion-resistant material, special greases and a hygienic design are all musts. Using shaft guides and profile rollers running on shafts offers enormous advantages. The profile rollers required here are a special construction made of corrosion-resistant material that exceeds all standards.

Since no drawing was available, a sample had to be offered and finally produced. Special profile track rollers have already proven their worth in wide-ranging applications. The customer is more than happy that Blässinger offers an inexpensive alternative to the original spare parts supplied by the system manufacturer. For decades, Blässinger has been supplying profile rollers with individual geometries and made of special materials for extreme applications.

Do you have any questions or need further information?

Contact Kemnat Head Office

CONTACT

Head office + Stuttgart branch

Josef Blässinger GmbH + Co. KG

Zeppelinstraße 18

73760 Ostfildern, Germany

Phone +49 711 16708-0

Fax +49 711 16708-81

Contact-Austria-AT

Contact

Location Austria

Blässinger GmbH

Salzburger Straße 24

8940 Liezen, Austria

Phone +43 3612 23410-0

Fax +43 3612 23410-4