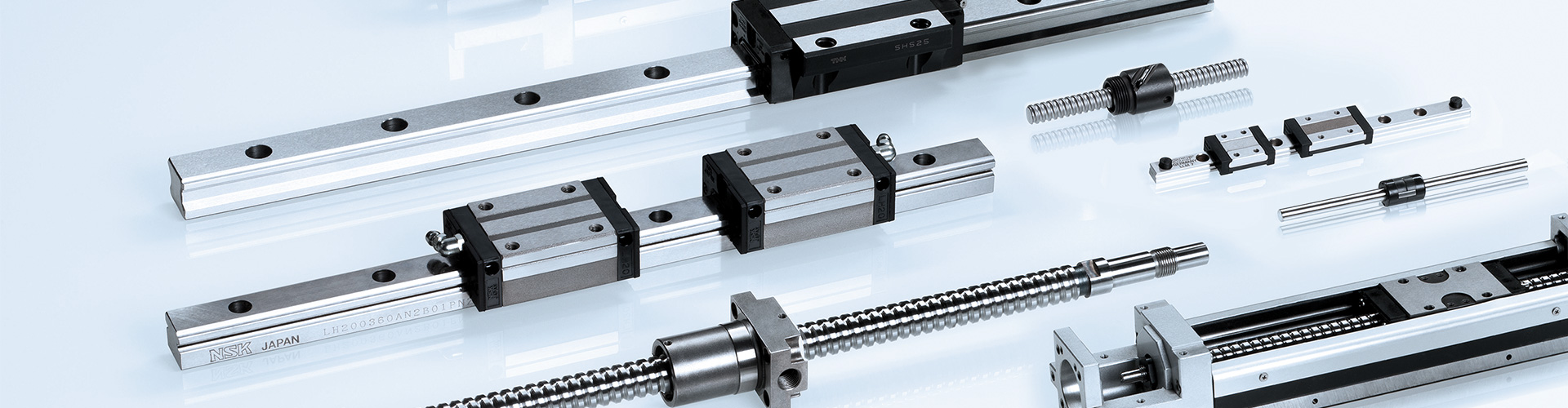

For shaft guides

- Shaft cutting and chamfering, cylindrical grinding and polishing axial/radial drilling, internal/external thread making, shaft end machining according to drawings

- Machining of supporting bodies according to drawings

- Making housings according to drawings

- Making shaft blocks according to drawings

- Cleaning linear ball bearings and greasing as specified

We assemble linear technology products in our machining centre within one day according to the wishes of our customers. We offer you individual mechanical processing such as end machining, additional drilling and thread and butt machining according to your specifications. We lubricate your linear ball bearings, rollers or carriages with lubricants according to your specifications especially for your application.

From miniature to heavy duty, whether single-start, multi-start, for handling tasks or machine tools – we can supply you with ball screws made to measure. Depending on your requirements we offer rolled, hard-whirled or ground spindles and for special applications we offer coated or stainless steel models. Our product range includes roller screws for very high loads or small pitches, and trapezoidal screws for simpler tasks.

We are happy to advise you on product selection or answer any questions you have, ranging from design to delivery.

Do you have any questions or need further information?

Contact Kemnat Head Office

CONTACT

Head office + Stuttgart branch

Josef Blässinger GmbH + Co. KG

Zeppelinstraße 18

73760 Ostfildern, Germany

Phone +49 711 16708-0

Fax +49 711 16708-81

Contact-Austria-AT

Contact

Location Austria

Blässinger GmbH

Salzburger Straße 24

8940 Liezen, Austria

Phone +43 3612 23410-0

Fax +43 3612 23410-4